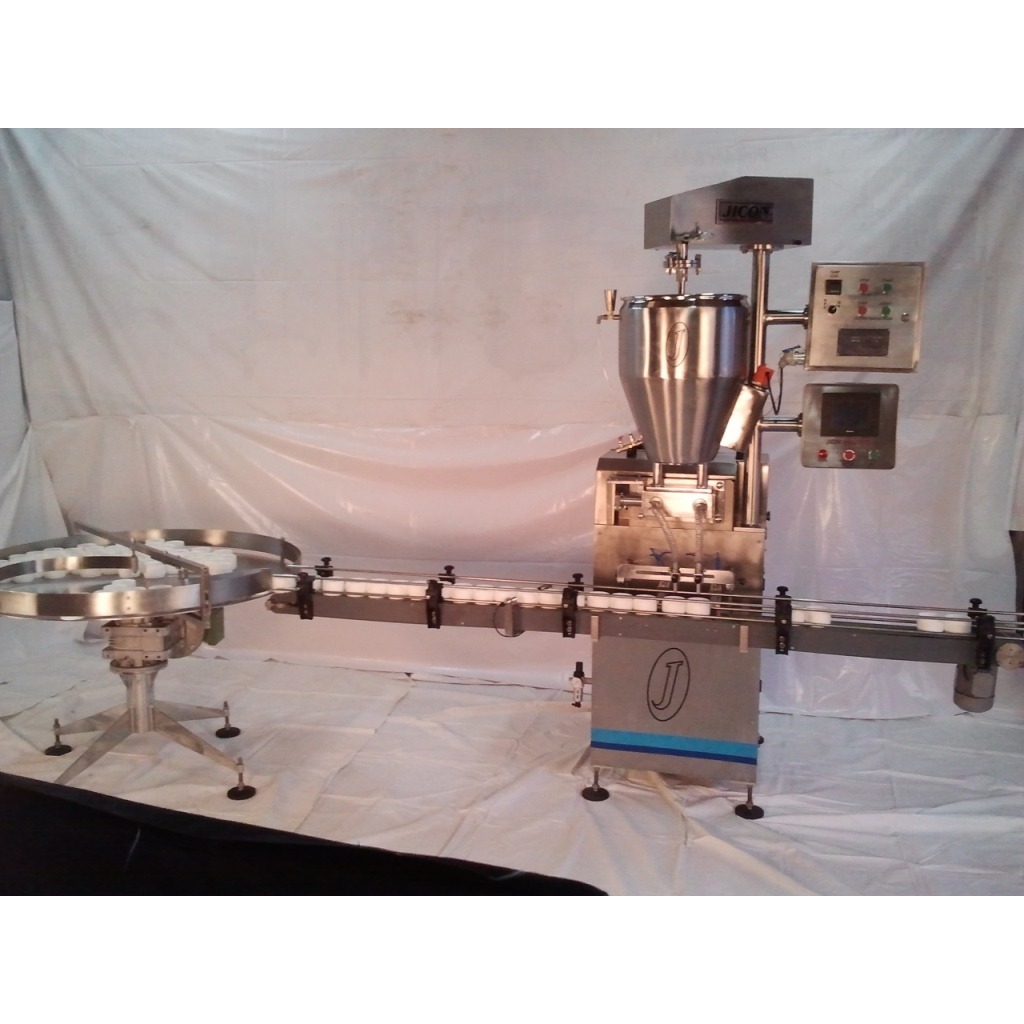

AUTOMATIC CONTAINER FILLING MACHINE

High speed automatic multi head container filling machine for filling cream, paste, ointment, wax polish, grease, jam, sauce etc. in plastic or tin containers or jars, bottles etc.

Containers like flat tins, bottles are loaded on turntable from where they are transferred onto conveyor belt where they are indexed into filling station. No-Container-No-Fill device will stop dozing operation if containers are not in place. SS jacketed hopper with 2 kw heater and stirrer can be provided as an option to facilitate easy filling of highly viscous products. Filled containers are transported over conveyor for further operations and handling.

FEATURES:

• PLC Controlled machine with colour Touch Screen

• Can fill creams of various viscosity

• No –Container – No – Fill interlock

• Tail Cutting arrangement after dozing

• Easy change over from one size to another

• Fill quantity can be accurately adjusted

• Fill accuracy up to ±0.5%

• Simple in operation and maintenance

Range:

Syringe Set(a): 10 gm to 50 gm

Syringe Set (b): 50 gm to 200 gm

(only for CF-2 and CF-3)

Syringe Set (c): 200 gm to 500 gm

(only for CF-2)

Keywords

CF

jam

jars

place

50 gm

10 gm

sauce

paste

cream

grease

option

500 gm

200 gm

stirrer

bottles

plastic

handling

one size

accuracy

FEATURES

ointment

turntable

operation

flat tins

wax polish

Syringe Set

2 kw heater

Easy change

easy filling

conveyor belt

Fill quantity

tin containers

Fill interlock

filling station

viscous products

Filled containers

various viscosity

maintenance Range

SS jacketed hopper

colour Touch Screen

PLC Controlled machine

Tail Cutting arrangement

No-Container-No-Fill device

AUTOMATIC CONTAINER FILLING MACHINE

High speed automatic multi head container filling machine